State of the Art

Warm Isostatic Presses

Innovators of WIP Technology

AIP designs and builds cutting edge Warm Isostatic Presses for many industrial applications. These systems can be gas or liquid pressurized and are often used for plastics and laminated products.

Warm Isostatic Presses Built for You

WIPs are usually purpose built and can be designed to accommodate low pressure all the way to extreme pressures, depending on your needs. Liquid WIP systems range to 250 C and gas WIP systems can go to 500 C. Both cold and hot wall versions can be supplied or designed to order. AIP has worked with many companies around the globe to develop the molding and technology required to make the process cost effective and possible. AIP has toll WIP capabilities and can offer testing to interested parties.

Speak with a Specialist

Contact our team to get answers from highly trained industry professionals!

Gas WIP

Gas Warm Isostatic Presses

Gas Warm Isostatic Presses, with capabilities up to 500 C, offer versatile molding solutions for a range of high-temperature applications.

Liquid WIP

Liquid Warm Isostatic Presses

Liquid Warm Isostatic Presses, reaching up to 250 C, are ideal for plastics and laminates, adaptable from low to extreme pressures.

Speak with a Specialist

Contact our team to get answers from highly trained industry professionals!

Why American Isostatic Presses?

Expertise

Over 30 years of knowledge and experience guides our work.

Integrity

Privately held with longstanding client relationships in all sectors.

Quality

Award-winning and board certified craftsmanship you can trust.

Our Superior Press Technology is Worldwide

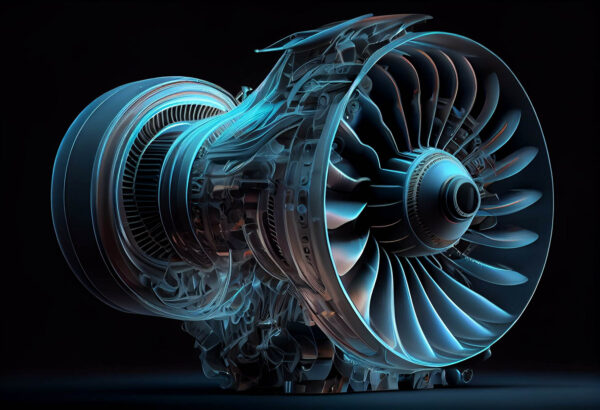

Aerospace

Advanced isostatic presses ensure aerospace components meet rigorous standards of strength and precision.

Energy

Efficient, high-quality component manufacturing for the energy industry is supported by specialized presses.

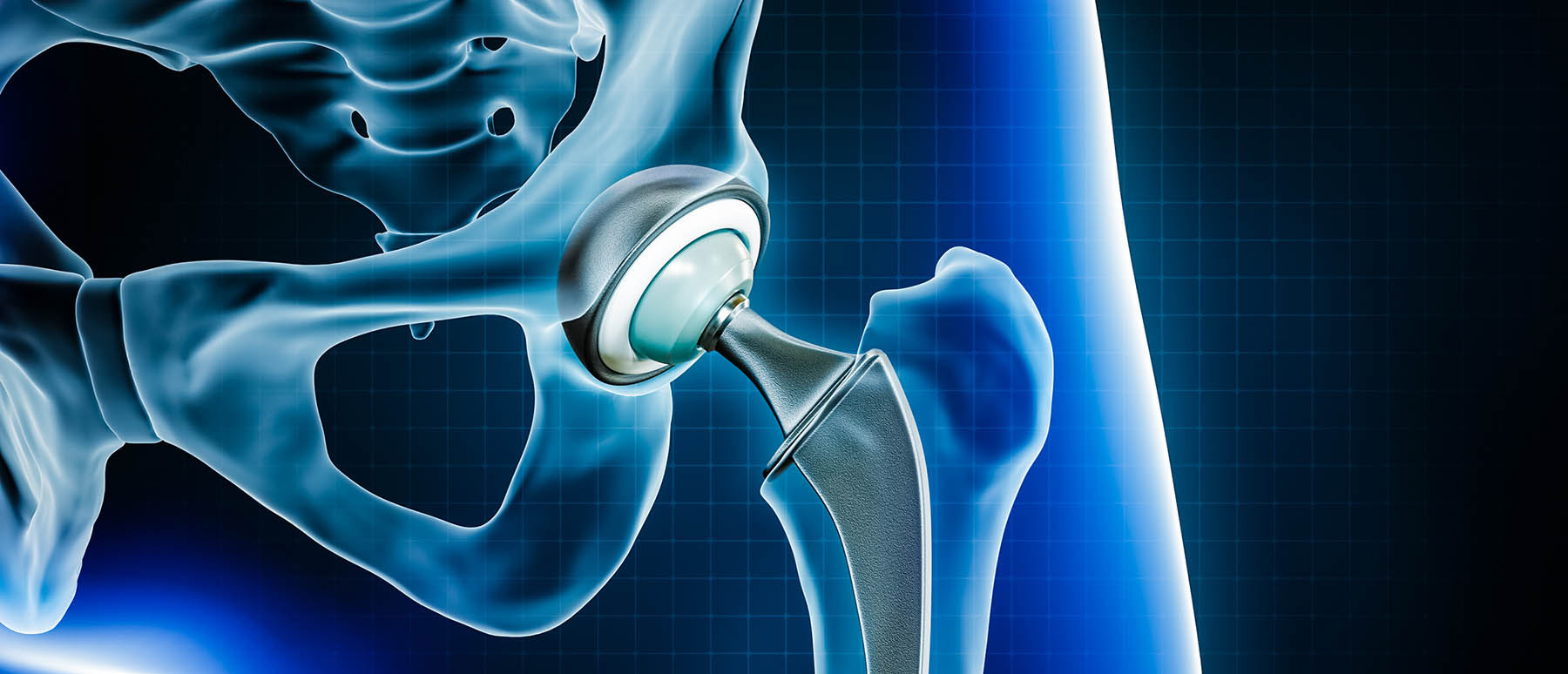

Medical

Isostatic presses enhance the development of medical devices, ensuring durability and precision.

Defense

Robust isostatic presses are essential for producing high-standard, reliable components for defense.

Automotive

Automotive manufacturing benefits from presses that enhance component durability and accuracy.

Space

Specialized presses support space exploration by providing components that withstand extreme conditions.