The Industry Innovator

American Isostatic Presses is proud of our reputation as the industry innovator in hot and cold isostatic pressing technology. With 30 years of experience, our expertise and reliable craftsmanship is unmatched. See for yourself why AIP systems are being used by major corporations and world governments around the globe

A Culture of Excellence

AIP manufactures a wide variety of temperature and pressure products including HIP, CIP, WIP, SinterHIPs, Vacuum Furnaces, Computer Control Systems, Thermocouples, and Spare Parts. We take great pride in our innovative products and systems, as well as our world class team of engineers and manufacturing experts. Explore our full range of best in class products built to operate reliably around the clock for tens of thousands of cycles.

Isostatic Pressing Technology

Pressure Vessel Manufacturing

Furnaces, Vacuums, and Controls

Custom Industrial Solutions

Speak with a Specialist

Contact our team to get answers from highly trained industry professionals!

Our Superior Press Technology is Worldwide

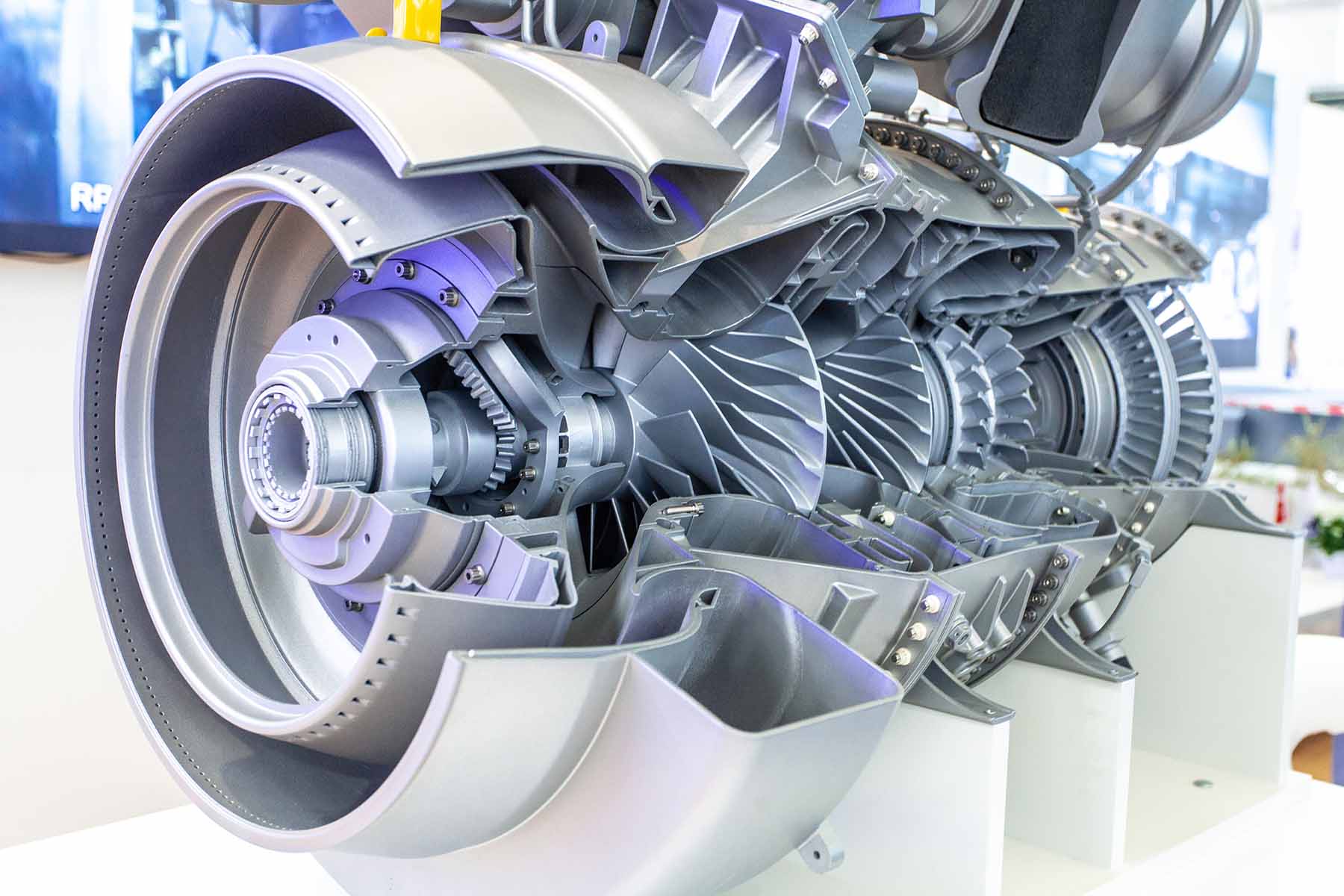

Aerospace

Advanced isostatic presses ensure aerospace components meet rigorous standards of strength and precision.

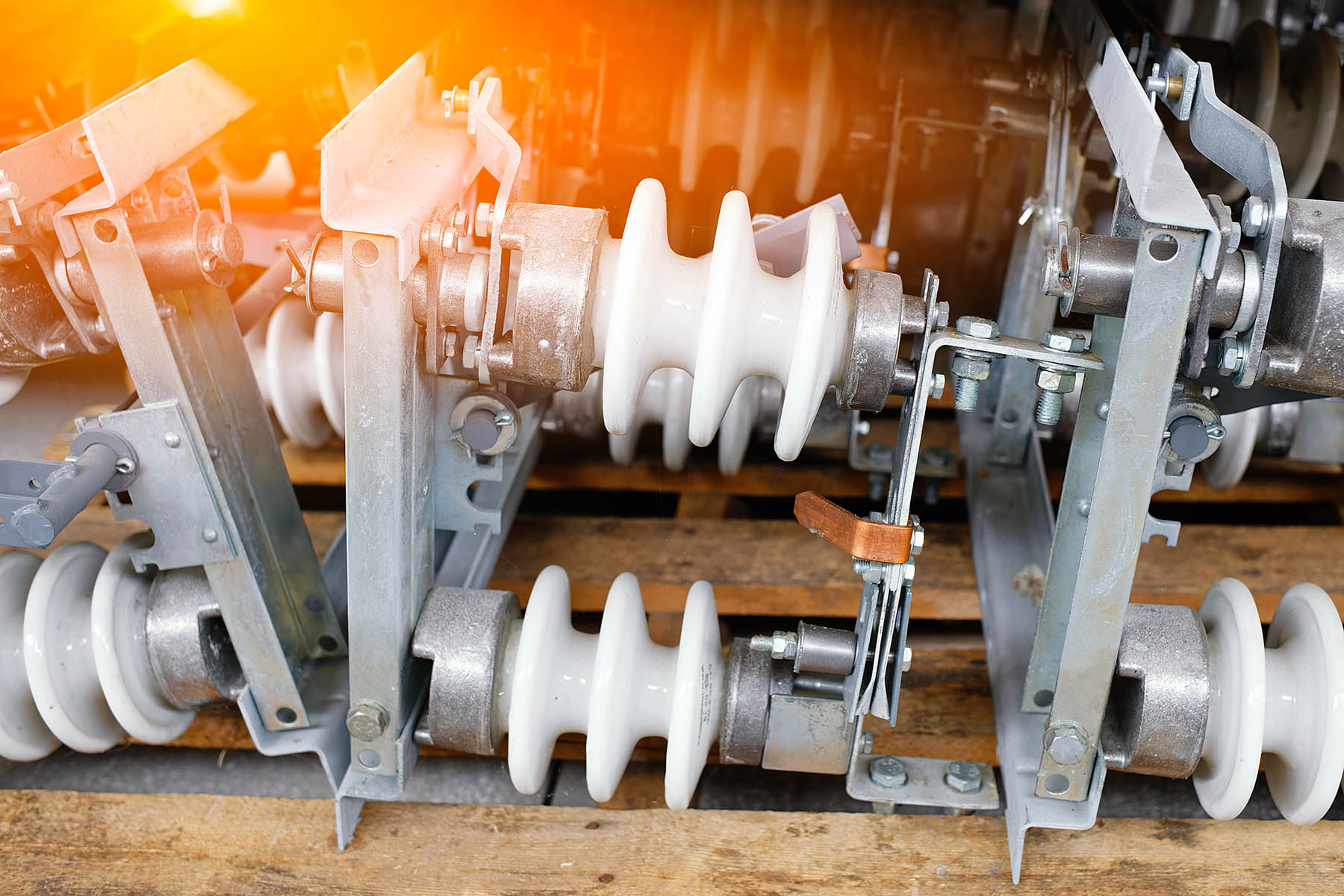

Energy

Efficient, high-quality component manufacturing for the energy industry is supported by specialized presses.

Medical

Isostatic presses enhance the development of medical devices, ensuring durability and precision.

Defense

Robust isostatic presses are essential for producing high-standard, reliable components for defense.

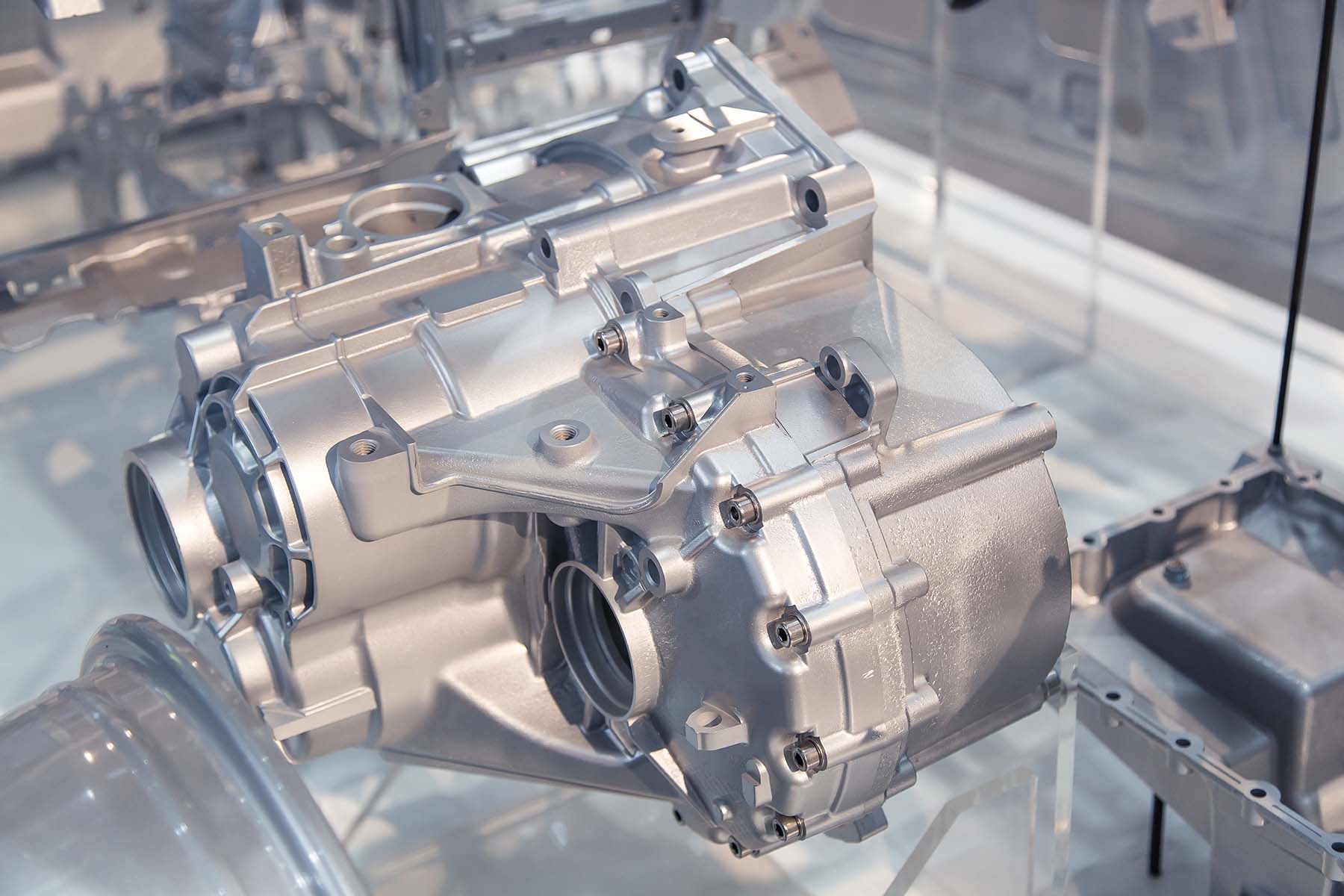

Automotive

Automotive manufacturing benefits from presses that enhance component durability and accuracy.

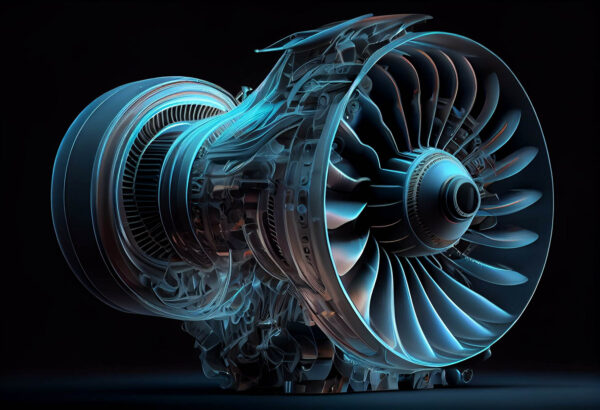

Space

Specialized presses support space exploration by providing components that withstand extreme conditions.

Speak with a Specialist

Contact our team to get answers from highly trained industry professionals!

Why American Isostatic Presses?

Expertise

Over 30 years of knowledge and experience guides our work.

Integrity

Privately held with longstanding client relationships in all sectors.

Quality